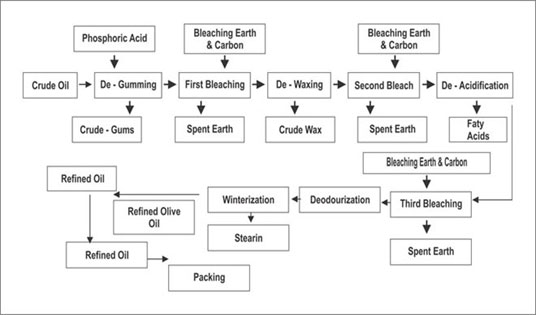

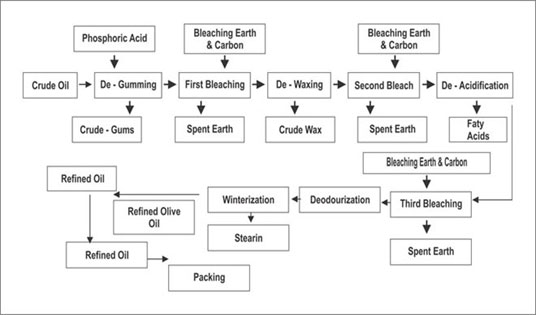

Refining employs a process of removing impurities present in edible oil. Impurities are primarily of two kinds, oil soluble impurities and oil insoluble impurities. Oil soluble impurities are gums (phosphotides) that have high melting points and saturated fats (stearin) whereas oil insoluble impurities are sand, dust, straw, seed fragments etc.Following is the process we follow

De-gumming - In this process, gums (phosphotides) are separated from crude oil by adding phosphoric acid and water at 65ºC-70ºC after which, the crude oil is processed through a high speed centrifugal machine resulting in a separation of gums (phosphotides) from the oil. Gums (phosphotides) are produced as a by- product.

First Bleaching - Bleaching is a process in which active bleaching earth and carbon is added to crude oil that has been heated and dried in a bleacher. The color pigments present in the degummed oil are soaked by the surface of the bleaching earth and carbon. The processed rice bran oil is filtered through pressure leaf filters of a continuous type. Therefore the processed oil assumes a light color and spent earth is the resultant by-product of this process.

De-waxing - In this process, the processed oil goes is subjected to controlled cooling in a crystallizer for a substantial period of time that results in the vegetable wax present in the oil being crystallized and separated. The filtered oil is produced as de-waxed oil and hard waxes are detained as vegetable waxes.

Second Bleaching - This process is identical to the process followed under the ‗First Bleaching' , mentioned above and results in further reduction in the color of the oil.

De-acidification - This process is also referred to as the ‗physical' refining of oil. It involves heating the processed oil at 250ºC under high vacuum (1-2 Torr), which results in free fatty acids present in the oil being distilled. The free fatty acids are obtained as a by-product, leaving behind de-acidified oil.

Third Bleaching - Third bleaching is identical to ‗First Bleaching' and ‗Second Bleaching' and results in a further reduction in the color.

De-odorization - In this process, processed oil is heated up to 220ºC-230ºC under high vaccum (1-2 torr) in a specifically designed deodorizer. This process removes the peculiar odour associated with the oil, in addition to removing additional color bodies present in the processed oil. The result is odourless refined oil.

Winterization - The purpose of this process is to remove the high melting point saturated fats (stearin). The oil is subjected to controlled cooling and freezing temperatures in a specially designed crystallizer that is based on a patented design of a German company, which results in a drastic reduction of trans-fatty acid for a substantial period of time. The high melting point saturated fats (stearin) are crystallized at a specific temperature and are filtered away in the filter press. The resulting oil has a low cloud point i.e. the refined oil retains transparency even in cold weather conditions.